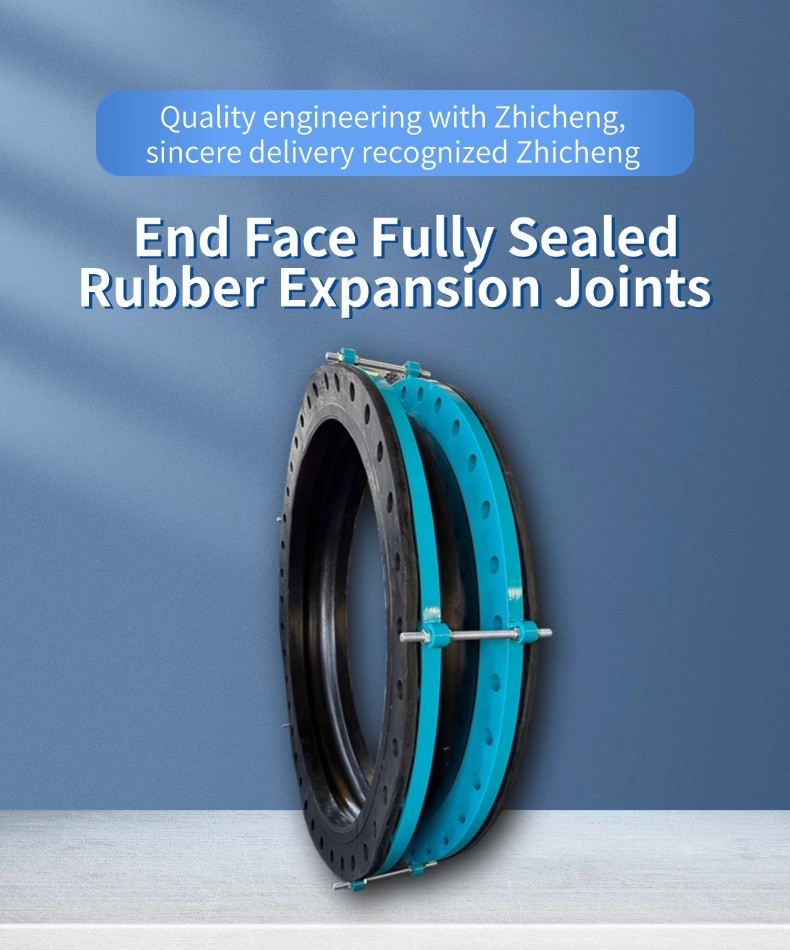

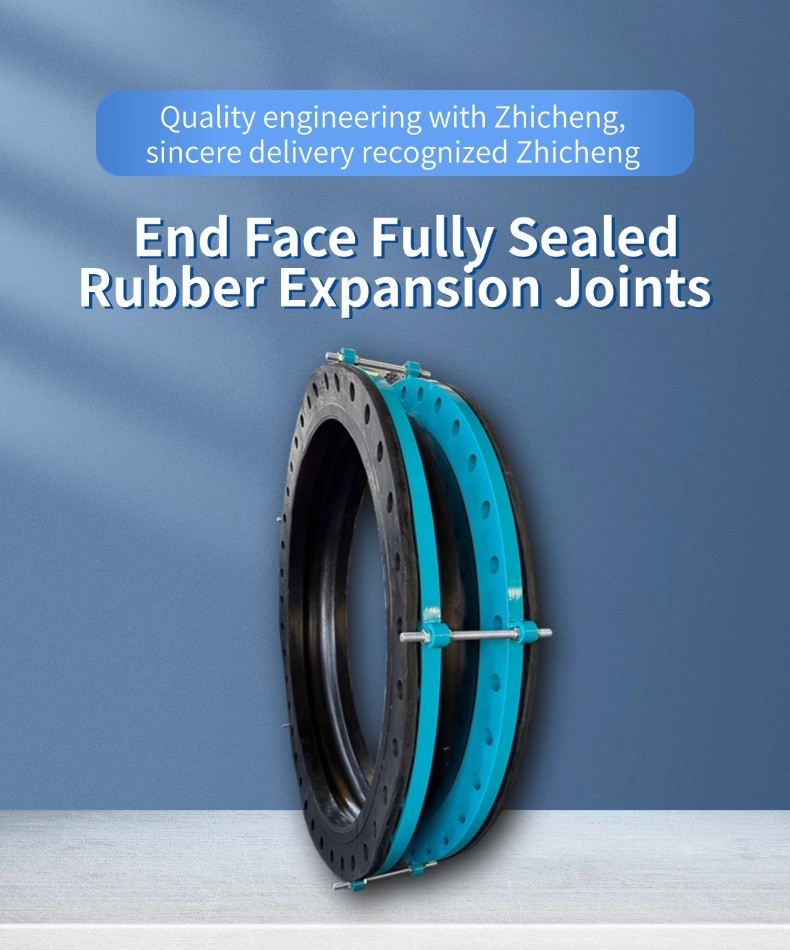

End Face Fully Sealed Rubber Expansion Joints

Company video

A Rubber Expansion Joint with Full Sealing Surface is a specialized

type of flexible

joint designed to accommodate thermal expansion, vibration, and

movement in

piping systems while ensuring a high level of sealing. It is

commonly used in various

industries such as water treatment, HVAC, chemical processing, and

more, where

leakage prevention is crucial.

| Material of rubber joint |

| NO. | Name | Material |

| 1 | Outer/inner rubber | NR, NBR, EPDM, SBR, BR etc. |

| 2 | Frame | Nylon card fabric |

| 3 | Pressurized ring | Steel wire strand |

| Technical conditions of rubber joint |

| Type | 1 | 2 | 3 |

| Working pressure(Kg f/cm2) | 1.0/10 | 1.6/16 | 2.5/25 |

| Explosion pressure(Kg f/cm2) | 2.0/20 | 3.0/30 | 4.5/45 |

| Vacuum value(mmHg) | 2.0(20) | 86.7(650) | 100(750) |

| Applicable temperature | -15℃ ~ +80 ℃ (-30℃~+150℃ special) |

| Applicable media | Air,compressed air,water,sea water,hot water,oil,acid and alkali

etc |

Installation parameters

Product picture

Key Features of Rubber Expansion Joint with Full Sealing Surface:

1. Full Sealing Surface:

The full sealing surface design refers to the expanded area around

the joint that

provides complete contact with the mating flange. This ensures an

excellent seal

and eliminates potential leakage points, even under high-pressure

conditions. This

type of joint is especially effective in systems where sealing

integrity is critical,

such as in high-pressure pipelines or systems with aggressive

media.

2. Flexibility and Absorption:

Rubber expansion joints with a full sealing surface are capable of

absorbing large

amounts of vibration and thermal expansion. The rubber material

itself is flexible,

allowing the joint to accommodate axial, lateral, and angular

movements without

compromising the system’s integrity.

3. Materials:

These joints are typically made from high-quality synthetic rubber

compounds such

as EPDM (Ethylene Propylene Diene Monomer), NBR (Nitrile Butadiene

Rubber),

or FKM (Fluorocarbon Rubber), depending on the application and the

type of media

the joint will be exposed to.

• EPDM is commonly used for water, air, and steam applications.

• NBR is suitable for oil, fuel, and other hydrocarbon-based

systems.

• FKM is used for aggressive chemicals and high-temperature

environments.

Package and ship

Delivery Time :

a.in stock:immediately b.sample:about 3 days c.OEM/ODM:about 15

DAYS

Show the strength of the factory

Q: Can you make the product as per client's requirement?

A: Yes, we can make it with your exact requirement.

Q: What are your payment terms?

A: T/T (30% as desposit, the rest 70% will be paid before

delivery), L/C

at sight.

Q: Where is your nearest loading port?

A: Shanghai, Qingdao or Tianjin, China.

Q: How can you guarantee the quality or any warranty?

A: If any quality problems during use, all the products can be

returned

or according to consumer's requests.

Q: Do you accept small quantity order?

A: Of course we do.

Q: And what is your shipment and delivery time?

A: By sea or air. Normally 7 to 14 Days for delivery, according to

your

order quantity. Pls send your detailed needs in the below and get a

quick reply!